2025-03-06

Clamped, centred and aligned level

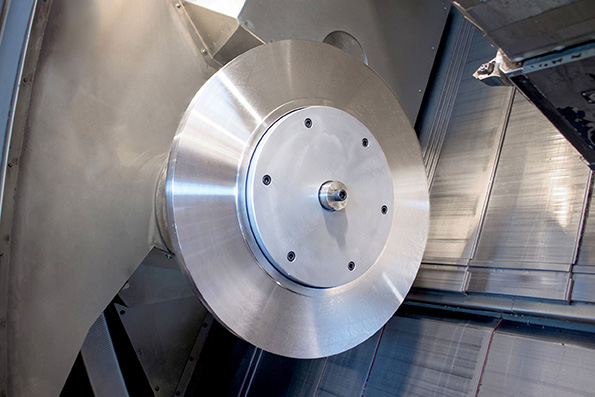

Flat Element Flange Mandrel from RINGSPANN optimises machining and balancing processes

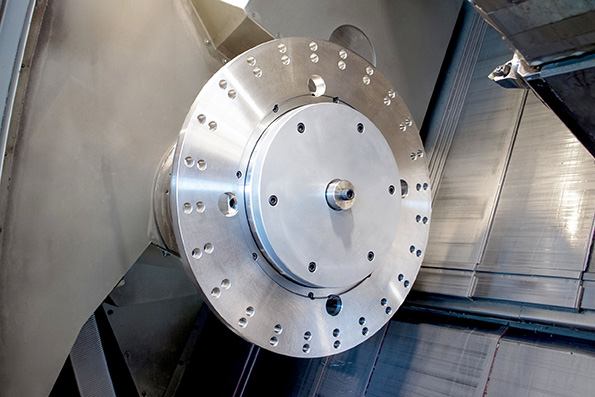

With the KFDF Flat Element Flange Mandrel, RINGSPANN offers an extremely compact precision clamping tool for optimising many turning, drilling, grinding, milling and balancing processes in gearbox construction, gear production and tool manufacturing. It scores with extremely precise concentricity, a short clamping length and a standard clamping diameter of up to 375 mm, which can be extended to up to 560 mm by using alternative clamping elements. Its flat clamping body centres the workpiece and aligns it level.

Bad Homburg, March 2025. – Turning and drilling of steel coupling elements, grinding carbide rolling rollers, milling aluminium gearbox covers or gear grinding of hollow shafts made of stainless steel are just a few examples of the wide range of applications of the KFDF Flat Element Flange Mandrel from RINGSPANN. They illustrate the versatility of this compact clamping fixture, whose domain is mechanical machining processes in particular, which place increased demands on precision. Apart from its concentricity of ≤ 0.01 mm, it ensures precise centring and a flat alignment of the clamped workpiece. "The uneven deformation of workpieces – a common problem, for example, when using three-jaw chucks – can be ruled out with our Flat Element Flange Mandrel thanks to complete 360° clamping," says Christoph Schulz, Product Manager Clamping Fixtures at RINGSPANN.

The KFDF is one of the group of purely mechanical precision clamping mandrels in the RINGSPANN portfolio and can be individually configured in the company's one-stop shop (web shop) in all standard variants for executable clamping diameters from 120 mm to 375 mm. In addition, the German manufacturer offers standardised Flat Elements that can be used to extend the clamping diameter up to 560 mm. Additional adaptations to different spindle connections, special workpieces or customer specifics can be realised by means of adapted holders, assembly rings, intermediate flanges or spring accumulators. "Within the framework of the geometry and the tolerance specifications of the workpieces, we can meet almost any customer request here," emphasises Christoph Schulz.

Powerful elasticity

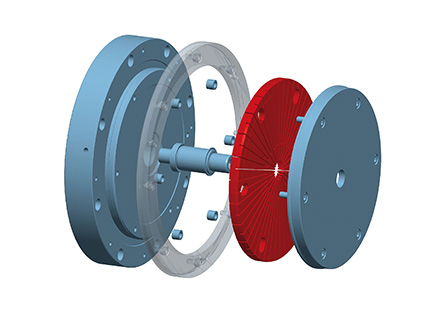

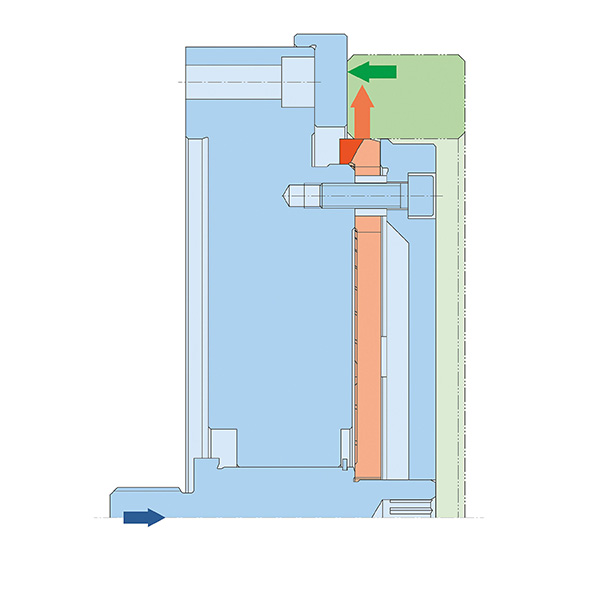

The KFDF from RINGSPANN is a system of six main components, the functional power plant of which is a prestressed, fan-shaped, slotted, round steel disc. The clamping diameter of the elastic flat element expands due to the axial actuation force introduced, so that both a radial clamping force and an axial face tightening force act on the workpiece. The workpiece is centred and aligned level at the same time. "The face tightening is carried out against a contact surface on the outer surface or an individually designed backstop ring," explains Christoph Schulz. The pressure pin is either connected to the power clamping device of a machine tool or is operated manually. RINGSPANN offers an optional assembly for manual clamping.

Versatile, efficient and safe

As with all clamping fixtures from RINGSPANN, the KFDF also focused on the factors of increasing flexibility and reducing set-up times in machining production. As a result, with this compact Flat Element Flange Mandrel, the company offers both manufacturers and users of machine tools a modern precision clamping system with which many turning, drilling, grinding and milling processes can be carried out extremely efficiently. Thanks to its high adaptability and easy handling, it is one of those clamping systems that can give the machining of annular and cylindrical workpieces, as well as housings with cylindrical bores, significant impetus in terms of process reliability and productivity. Since it works purely mechanically, it does not require a pneumatic or hydraulic energy supply. It is also suitable for both wet and dry processing. "And thanks to its high operational reliability and excellent concentricity, it is another clamping solution for many automated processes, especially in balancing technology," comments Christoph Schulz. ms