2017-07-20

The specialist for gearing technology and fine machining

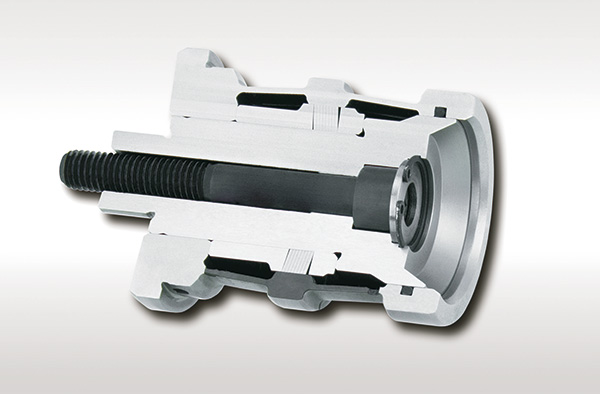

RINGSPANN presented its expanding sleeve mandrel at the EMO 2017

For manufacturers of gear wheels and suppliers in the area of metal-cutting fine processing, a visit to RINGSPANN’s trade fair stand at this year’s EMO is a must-see. That is where the Bad Homburg clamping fixture specialist will be showcasing its new expanding sleeve mandrel HDDS. This alternative to hydraulic expanding clamping tools has already proven its potential in initial high-precision gear manufacturing applications. RINGSPANN’s HDDS can take workpieces with bores of up to tolerance class IT10 and is convincing in practice thanks to a true running accuracy of ≤ 5 µm. You can find RINGSPANN at the EMO (18.-23.9.2017) in Hannover in Hall 3, Booth C40.

Bad Homburg, July 2017. – The production of spur or taper wheels for gear manufacturing is placing ever greater demands on machines and tools as quality and accuracy requirements have continued to grow over the past years in this area of fine machining. “Where gearing qualities of 8 or 9 in accordance with DIN 3961 used to be sufficient, today customers often demand gearing qualities of grades 7 or 6. And anyone who manufactures gear wheels for motorsports is further required to realise gearing qualities of 5 or even 4. Meanwhile, suppliers continue to be forced to operate under considerable cost pressure”, reports Volker Schlautmann. He is the director of the clamping fixture division of RINGSPANN and is therefore aware of the key role the deployed clamping tools play under these conditions. With the objective of being able to offer suppliers a clamping system that helps them to implement these increasing demands in quality while at the same time giving them more economic leeway, he paved the way for the development of a new expanding sleeve mandrel. This innovative inner clamping system with the abbreviation HDDS is one of the technology highlights at RINGSPANN’s trade fair stand at this year’s EMO in Hall 3 (Booth C40).

Economical and tolerant

The new expanding sleeve mandrel of RINGSPANN is designed as a construction consisting of several parts and is an extremely economical alternative to the hydraulic expanding clamping tools that are currently widespread in gearing technology. As Volker Schlautmann explains: “Our HDDS offers a true running accuracy of ≤ 5 µm and achieves an absolute expansion four times greater than that of most hydraulic clamping fixtures. It can therefore also take workpieces with bores of up to tolerance class IT10. With these characteristics alone, it is far superior to many hydraulic expanding clamping tools.” What also bears mentioning is the fact that most hydraulic clamping fixtures are only suited to take workpiece bores of up to tolerance class IT7.

The development of RINGSPANN’s new HDDS was already completed internally midway through last year. Since then, the mechanical inner clamping system has already drawn praise in a number of demanding applications. In the production of a Swiss gear manufacturer, for example, the HDDS proved its potential, backed up by solid data from technical measurements, in the high-precision grinding of spur wheels. There, the axial run-out and true running accuracy of the disc actuated bush clamping mandrel of RINGSPANN here were initially examined with a tactile measuring device accurate to the micrometre and subsequently verified on an original blank with a modern coordinate measuring system. “In both cases, our HDDS exceeded the customer’s expectations. In the test run the measuring device showed ≤ 2 µm for the axial run-out and ≤ 3 µm for the true running. The geometrical accuracy of the involute gearing (a term that designates the force-optimized shaping of the tooth flanks) for the original workpiece was well within the tolerance limits”, notes Volker Schlautmann.

Simplified automation thanks to large expansion

Many of the first applications not only document the high degree of precision of RINGSPANN’s new disc actuated bush clamping mandrel, but also show that it – not least due to its high expansion rate – supports the simple realisation of fully automated manufacturing concepts. Since hydraulic expanding clamping mandrels, for pure reasons of physics, have quite a small expansion rate, they demand a high kinematic precision for the handling devices employed for their feeding and positioning. This, however, requires significant investment in the measuring and control technology of the peripheral systems. “Our HDDS frees the user from this expenditure and provides him with an affordable entry into fully automated processing”, says clamping technology specialist Schlautmann.

At the same time, the new disc actuated bush clamping mandrel of RINGSPANN frees the user from another issue: Since it embodies a purely mechanical solution, its deployment is completely free of any risk of leakage as is the case for hydraulic clamping systems. This means a higher process safety during series processing, since any leak at a hydraulic expanding clamping tool always means process interruption, malfunction and repair. “The only potential source of abrasion for our HDDS is its clamping discs. These are however quality products from our own production that can be replaced very easily by the user – the clamping mandrel doesn’t even need to be taken from the spindle to do so”, underlines Volker Schlautmann.

Practical even with short clamping lengths

By the way: At the RINGSPANN’S EMO trade fair stand in Hall 3, the visitors will also discover that the new disc actuated bush clamping mandrel also proves to be a practical solution for the processing of workpieces with very short clamping lengths. “The mechanics of our HDDS perform a pull-back action, where the workpiece is pressed against a backstop and aligned. This process simultaneously ensures the precise centering and clamping of workpieces with short clamping lengths”, explains Volker Schlautmann. Even bores whose inner geometry is interrupted by a nut can be precisely and reliably clamped by the HDDS from RINGSPANN without any additional aids.